Innovative System

Wiicom’s PFTC is an innovative system for pneumatic work tool objectivation. The system is equipped with a touchscreen display, with an intuitive graphic interface for the configuration settings and work cycle management.

The PFTC can be connected via wifi to an existent network or can be used as a hotspot, creating his own network (infrastructure), in order to manage the data communication. The PFTC can be also connected via Ethernet trough the network installed in the plant.

Real Time Monitoring

PFTC’s advanced and highly configurable software is able to get a real time control over all operations performed by the tool and all outcomes.

The operations that can be edited and set by the operator via software/display and the system can be selected between three different automation level.

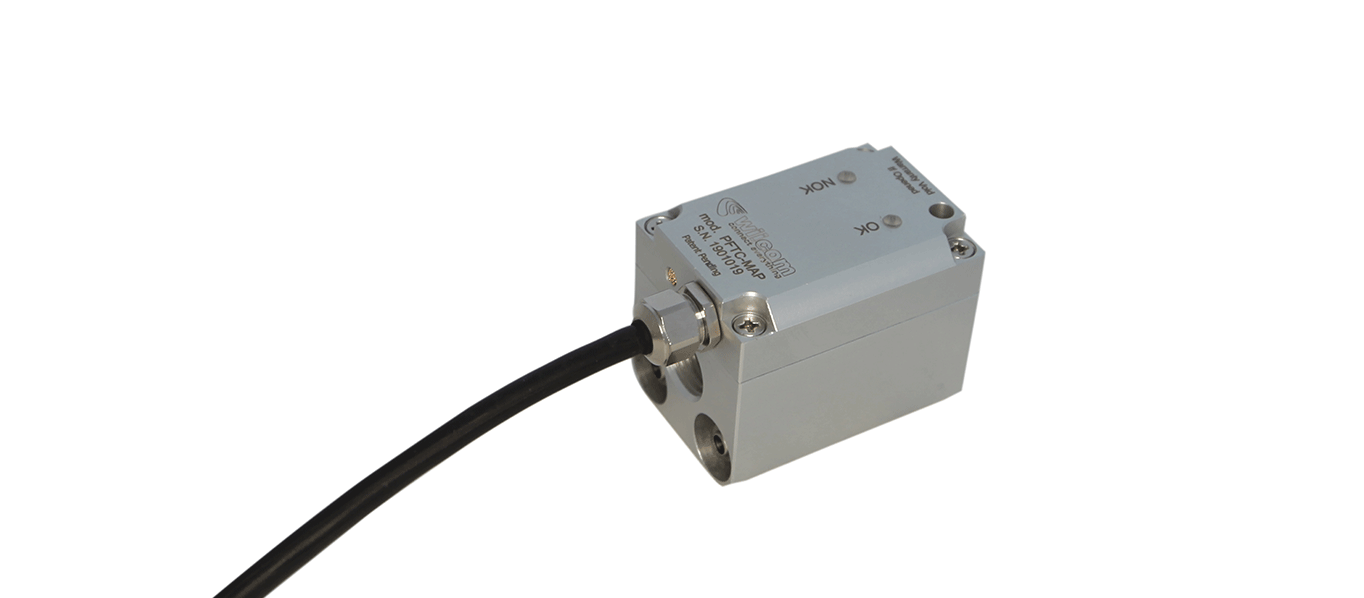

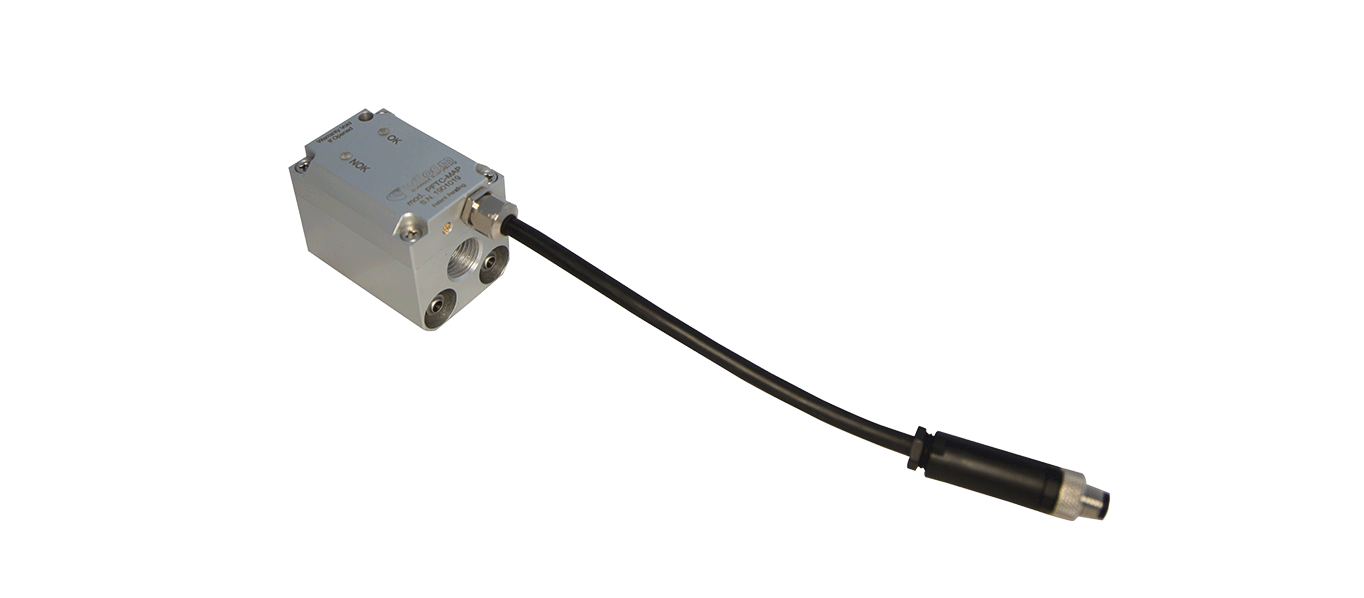

Retrofittable

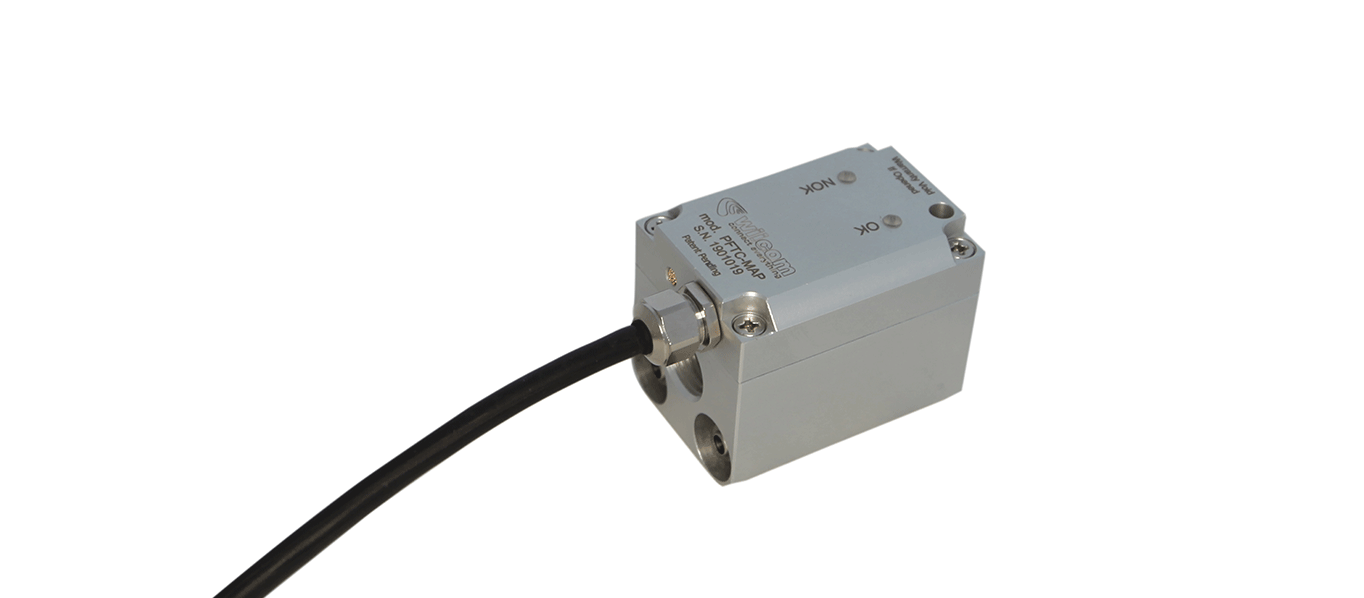

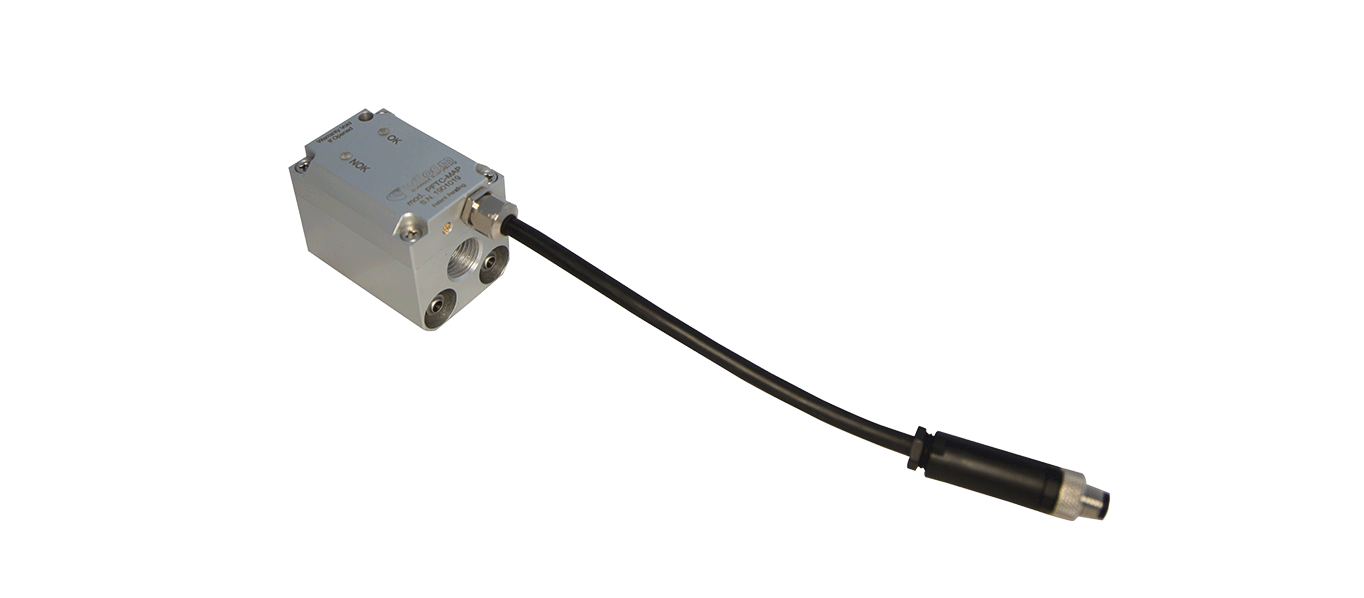

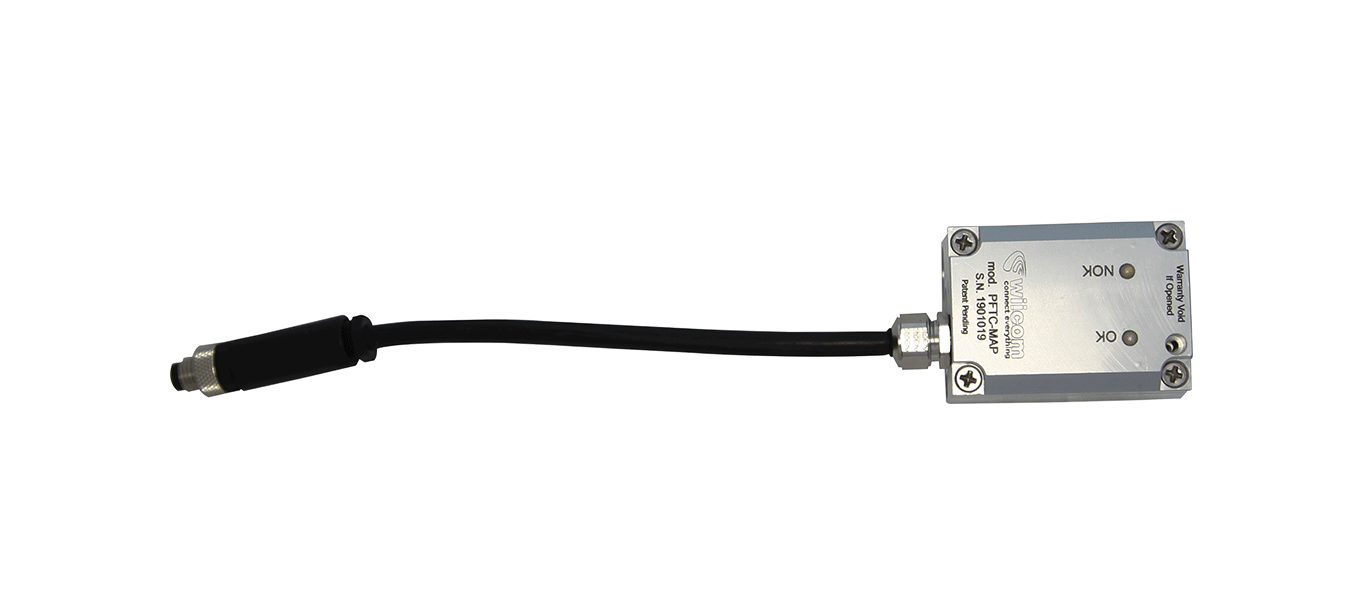

The retrofit can be done on every existing pneumatic tool and it provides an accurate and punctual monitoring of the air pressure, through its electromechanics sensor system developed by Wiicom. PFTC is compatible, flexible and highly integrated with all pneumatic tools.

The retrofit allows all machine reuse without any modifications of the pneumatic tools already in place,ensuring significant savings.

WLAN Functions | 802.11ac, Bluetooth 5.0 BLE |

RF Frequency Band | 2.4 GHz, 5 GHz |

Network Protocol | Gigabit Ethernet |

Pressure range | 0 – 10 BAR |

Touch Screen | 7’’ or 12’’ |

Communication Protocol | CAN Bus High Speed |

MEC CPU | Broadcom BCM2711, Quad core Cortex-A72

(ARM v8) 64-bit SoC @ 1.5GHz |

MEC SDRAM | 4GB |

ENVIRONMENT CONDITIONS

Operating Temperature | Industrial (0°C to +50°C) |

Dimensions | MEC 34.5 x 18.5 x 26.5 cm; MAP 5 x 3.7 x 4.1 cm |

POWER SUPPLY

Supply Voltage | MEC 220-240V AC (50 Hz); MAP 5.5 – 7V CC

|

Consumption | MEC 1.6 A; MAP 80 mA(@7V) |

Is this what are you looking for?

Contact us! We can help you out to find a quick, cheap & right solution